In today’s highly competitive machining and tooling industry, selecting the right end mill manufacturer goes far beyond price. A reliable manufacturer is a strategic partner who can ensure stable quality, reduce downtime, and provide the technical support necessary for long-term success. This guide highlights the key factors to consider when choosing your next tooling partner.

1. Key Indicators for Evaluating a Manufacturer

When comparing manufacturers, purchasing managers and engineers should carefully evaluate these core areas:

- Product Quality and Consistency

- Check if the manufacturer uses high-grade tungsten carbide materials produced with advanced powder metallurgy.

- Review precision standards: ISO, DIN, or JIS compliance ensures consistency across batches.

- Ask for quality inspection reports or third-party certifications to confirm credibility.

- Delivery Reliability and Lead Time

- A good manufacturer should maintain adequate inventory and stable production capacity.

- On-time delivery reduces costly downtime and keeps your production schedule stable.

- After-Sales Support and Technical Expertise

- Look for manufacturers that provide cutting parameter recommendations, tool selection advice, and troubleshooting guidance.

- Value-added services such as regrinding, re-coating, or custom-made solutions can help extend tool life and reduce costs.

2. Beyond Price: Evaluating Manufacturer Capabilities

Price is often the first thing buyers notice—but in the world of precision machining, lowest cost does not equal best value. Instead, focus on the manufacturer’s overall capabilities:

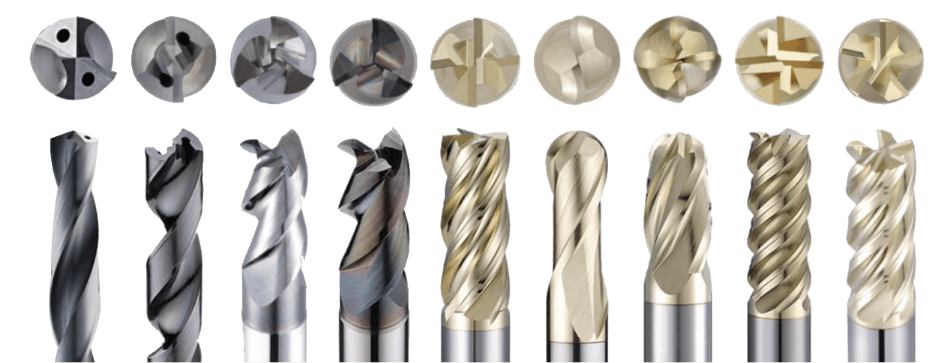

- Innovation and R&D

- Does the manufacturer continuously invest in tool geometry design, coating technology, or advanced CNC grinding equipment?

- Innovative manufacturers can help you stay competitive as machining challenges evolve.

- Industry Applications

- Manufacturers with experience in automotive, aerospace, mold-making, or medical device industries are often more versatile.

- They can provide application-specific solutions that reduce trial-and-error costs.

- Scalability and Partnership Potential

- A strong manufacturer can grow with your business, supplying both small-batch customized tools and large-volume production runs.

- Long-term partnerships reduce hidden costs associated with frequent manufacturer changes.

3. Building a Long-Term Partnership

The most successful companies don’t just buy tools—they build strategic partnerships with their manufacturers. A trusted manufacturer should:

- Provide transparent communication and proactively share new product updates.

- Offer training or knowledge-sharing sessions to improve your team’s machining efficiency.

- Act as a problem-solving partner rather than just a product vendor.

4. Recommended Manufacturer

When searching for a reliable partner, consider established tooling specialists such as JIN LI CHENG. With years of expertise in end mill manufacturing, the company emphasizes:

- High-precision production standards that meet global quality benchmarks.

- Flexible solutions ranging from standard to customized end mills.

- Strong after-sales service to support customers in different industries worldwide.

This kind of manufacturer demonstrates how quality, service, and long-term reliability matter more than price alone.

5. Conclusion

Choosing a end mill manufacturer is not just a procurement decision—it’s a strategic move that impacts machining quality, production costs, and your company’s competitiveness. By focusing on quality, delivery, technical support, and partnership potential, you can build a supply chain that sustains growth.

If your company is seeking a reliable tungsten carbide end mill partner, explore trusted manufacturers like JIN LI CHENG to secure high-quality tools backed by professional service.