For brand managers and procurement specialists in the hardware industry, sustainability has decisively shifted. It is no longer a peripheral chapter in a corporate social responsibility report but a core metric for sourcing, product design, and long-term competitiveness. Among the various pathways to a smaller environmental footprint, integrating Post-Consumer Recycled (PCR) materials stands out as one of the most direct and measurable actions a manufacturing partner can take. However, transitioning to PCR plastics in durable products like locks is not a simple material swap—it is a strategic decision that intersects with engineering, compliance, cost, and brand narrative.

Demystifying Performance: The Reality of PCR in Durable Hardware

A significant barrier to adoption is the perceived trade-off between sustainability and performance. It’s time to move past these myths with modern material science and proven industry practices.

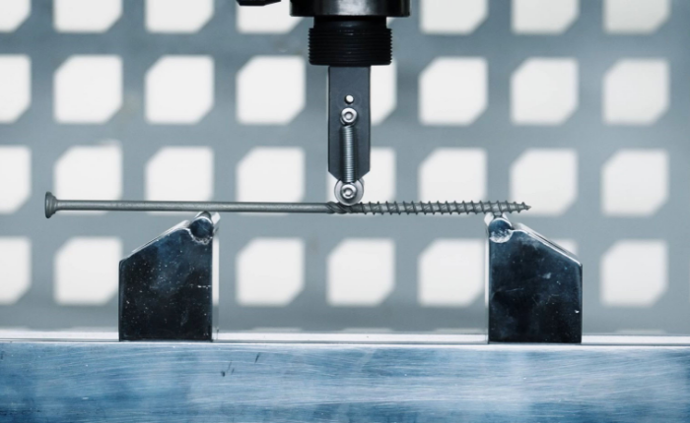

- Myth 1: The Strength Sacrifice. The assumption that recycled plastic is inherently weaker is outdated. Advanced sorting, purification, and polymer modification techniques now yield high-performance PCR compounds. For critical applications, leading manufacturers are validating these materials through rigorous protocols. For instance, in developing PCR-based cables for security locks, Sinox’s R&D center conducted over six months of intensive testing focused on strength & durability, processing consistency, and long-term performance under environmental simulation. The resulting product, backed by a complete TC Report, demonstrates that PCR materials can meet the stringent requirements for tensile strength and longevity expected in demanding hardware.

- Myth 2: The Aesthetic Compromise. Concerns about inconsistent color, texture, or surface finish are valid but solvable. Through masterbatch engineering and controlled processing parameters, manufacturers can achieve a consistent, high-quality finish with PCR resins. This allows brands to deliver on their premium look and feel without compromising their environmental goals.

The Strategic Value Proposition: Why Brands Should Mandate PCR

Specifying PCR materials transcends environmental stewardship; it delivers tangible business value to forward-thinking brands.

- Future-Proofing Against Regulation. Proactively adopting PCR is a strategic risk mitigation tool. Regions like the European Union are implementing plastics taxes and mandatory recycled content laws. Brands that have already established supply chains for PCR-compliant products will avoid disruptive, costly scrambles to comply.

- Enhancing Cost and Supply Resilience. While pricing fluctuates, PCR materials can provide a buffer against the volatility of virgin plastic prices. Building a diversified material portfolio enhances long-term supply chain stability.

- Building a Credible Product Narrative. In an era of greenwashing skepticism, PCR content offers a quantifiable and verifiable claim. It provides marketing teams with a substantive story rooted in circular economy principles.

- Driving Collaborative Innovation. Partnering with a manufacturer experienced in PCR integration fosters innovation. It challenges teams to re-evaluate designs for efficiency and can even lead to new product categories.

A Practical Framework for Brand and Manufacturer Collaboration

Transitioning to PCR successfully requires a structured partnership. Brands should seek manufacturers who can navigate this journey with transparency and proven methodology.

- Phase 1: Define Goals and Specifications. Is the target a specific PCR percentage, a carbon footprint reduction, or alignment with a certification? Clear, shared targets from the outset are crucial.

- Phase 2: Co-Develop and Rigorously Test. This phase is non-negotiable. It involves joint material selection and prototype testing. Brands should look for partners who undertake comprehensive validation, similar to the multi-dimensional testing approach (covering strength, consistency, and aging) employed in the aforementioned lock cable development case. Requesting and reviewing detailed test reports and certifications is key to ensuring real-world performance.

- Phase 3: Ensure Transparency and Traceability. Responsible sourcing is key. Partners must provide reliable chain-of-custody documentation to verify the PCR content’s origin, ensuring claims are authentic and audit-ready.

Conclusion: Sustainable Manufacturing as Supply Chain Resilience

The integration of PCR materials is a definitive marker of a mature, forward-looking manufacturing partnership. For brands, it represents a strategic investment in a more resilient, compliant, and market-relevant supply chain.

The question is no longer if sustainable manufacturing will become the standard, but how quickly brands can adapt. By making material choice a primary design criterion and partnering with manufacturers who have proven PCR expertise and a rigorous validation mindset, brands can turn environmental responsibility into a powerful component of their product’s value—and their own competitive durability.

The following article is for anyone interested in the innovative developments that PCR brings to the lock industry.

- Redefining Locks with PCR Materials: Sinox R&D Center’s Breakthrough for a Secure and Sustainable Future

- Closing the Loop: Recycled Materials in Tech Hardware

- PCR Environmental Trend: SINOX Innovative Computer Peripheral RL0837