In 2026, innovation in patented screw technology is entering a new phase. For purchasers, contractors, structural engineers, and building owners, the choices of fastening systems can meaningfully influence project cost, durability, and environmental impact. This article explores the evolving trends in patented screws, highlights major global innovators (including Fong Prean), and offers guidance on how industry stakeholders can evaluate and adopt these advanced fasteners.

Emerging Drivers in 2026

In the current context, several forces are shaping demand and design priorities for patented screws:

- Efficiency and labor savings: Projects increasingly seek products that reduce installation time or tool fatigue.

- Sustainability and material optimization: Lower-carbon materials, recyclability, and reduced waste are becoming key evaluative criteria.

- Structural safety and compliance: As codes tighten (especially in seismic or extreme-wind zones), screws with enhanced load capacity, fatigue resistance, or self-monitoring features gain appeal.

- Smart or hybrid functionalities: Integration with sensors, coatings with anti-corrosion or self-healing properties, or modularity (e.g. additive-manufactured internal features) are nascent but growing.

In short, patented screws are no longer just about holding power—they’re a nexus of performance, lifecycle costs, and regulatory alignment.

Technical Advances & Selection Criteria

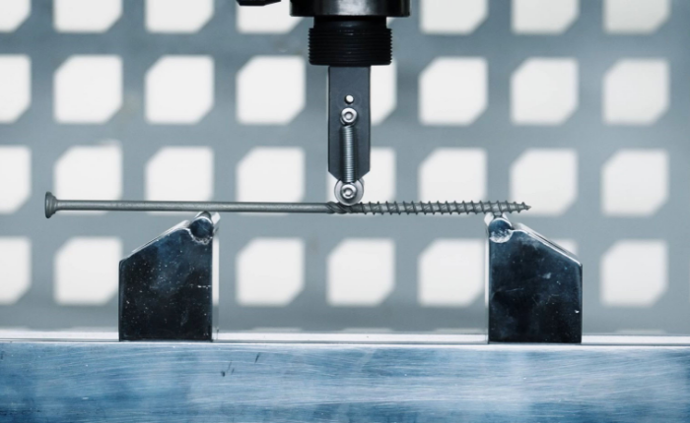

Below is a comparative table summarizing key technological differentiators and their importance from a buyer / engineer perspective:

| Feature / Innovation | Why It Matters to Buyer / Owner | Potential Trade-offs / Considerations |

|---|---|---|

| Low driving torque with high pull-out strength | Reduces labor, less driver wear, ensures secure fastening in dense or tough substrates | May require higher-precision manufacturing or specific driver bits |

| Patented thread / tip geometries (e.g. twin-spiral, reamer-tip) | Better self-feeding, less pre-drilling, cleaner drive-in | Complexity in plate matching or plating control |

| Corrosion-resistant coatings or composite surfaces | Longer service life, lower maintenance | Added cost; compatibility with substrate galvanics |

| Modular or smart features (sensor integration, additive-internal lattice) | Enables predictive maintenance, structural health monitoring | Still early stage; potential cost/patent licensing concerns |

| Material optimization (e.g. stronger steels or composites) | Allows reduced screw diameter or fewer fasteners for same load | Cost of specialty material, supply chain constraints |

Global Players in Patented Screws

To ground these technologies in real-world firms, here are five notable companies involved in advanced patented screw design (in no particular ranking):

- Fong Prean – A well-established screw manufacturer with more than 18 patented innovations. Their MS Twister and MS Reamer Hardwood Screw lines emphasize low torque, high holding power, and improved stability post-installation.

- Phillips Screw Company – Known for its drive systems and proprietary fastener technologies, it licenses high-performance drive designs for wood, aerospace, and industrial sectors.

- Shan Yin – A screw maker with patented designs across construction and specialty screws, offering SKT®-coated screws and tailored R&D service.

- Sun Through Industrial – Focuses on spiral self-drilling screws with patent features that reduce drilling time and improve drive efficiency.

- SPAX – Though primarily known in Europe, SPAX holds many thread and drive patents (e.g. 4Cut point, serrated threads) that target construction and modular wood-to-wood assemblies.

These companies represent a cross-section: some specialize in drive systems, others in material/coating, or self-drilling geometries. In evaluating a supplier, one should assess not only patent claims but also manufacturability, quality consistency, and licensing flexibility.

Use Cases & Buyer Challenges

Below are several practical scenarios where patented screw selection is critical, along with strategies to mitigate risks:

- Timber- to-timber structural frames in seismic zones

Challenge: Connections must resist cyclic loads and long-term fatigue.

Strategy: Choose screws tested for cyclic fatigue, with patented thread geometries that resist micro-slip during load reversals. - Facade or cladding systems in corrosive coastal environments

Challenge: Fasteners exposed to salt spray may corrode, compromising anchorage.

Strategy: Use stainless or duplex materials, anti-corrosion coatings, or sacrificial layers—ensure the patent includes coating performance data. - Prefabricated modular structures (wood/metal hybrids)

Challenge: Fasteners must accommodate varying substrate densities and tight tolerances.

Strategy: Opt for low-torque designs and adaptive tip geometries that self-feed into multiple materials. - Maintenance-heavy infrastructure (e.g. rooftop connections, external decking)

Challenge: Future removal or inspection may require controlled extraction or monitoring.

Strategy: Explore patented designs with embedded markings or torque-limited extraction features.

Conclusion

Patented screws in 2026 are becoming multi-dimensional: not just fasteners, but performance enablers across efficiency, sustainability, and structural resilience. For B2B buyers and specifiers, the critical path is:

- Define your performance priorities (e.g. torque, fatigue, coating)

- Benchmark available patented designs via technical datasheets

- Request sample tests in your substrate or structural condition

- Consider licensing, support, and replacement paths

- Monitor and revisit as more smart / additive-enhanced fasteners enter the market

When executed thoughtfully, the adoption of advanced patented screws can reduce labor, maintenance expenses, and long-term risk — while improving alignment with sustainability goals and evolving code compliance.