Introduction

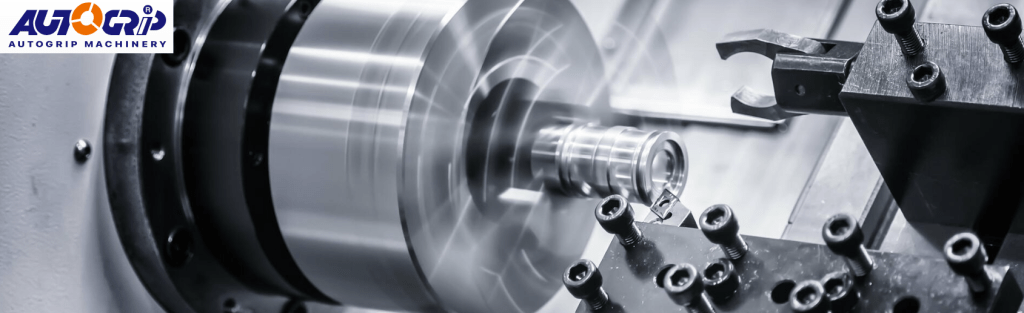

The lathe chuck market is a critical segment within the precision machining and metalworking industries. These components, particularly the 2-jaw, 3-jaw, and 4-jaw chucks, play a vital role in various industrial applications, including automotive, aerospace, and manufacturing. This report provides a comprehensive analysis of the marketing trends for these lathe chucks from 2025 to 2030, based on the latest available data and market insights.

Market Overview

Growth Projections

The global market for lathe chucks is witnessing significant growth, driven by the increasing demand for precision machining and automation. The overall chuck market is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2018 to 2030 (Industry Growth Insights). This growth is further supported by advancements in manufacturing technologies and the rising demand for precision machining in various industrial applications (GlobalInfoResearch).

Key Market Drivers

Several factors are driving the growth of the lathe chuck market:

Technological Advancements: The integration of automation and advanced materials in manufacturing processes is propelling the demand for sophisticated lathe chucks. These advancements enable higher precision and efficiency in machining operations (Market Research Intellect).

Expansion in Automotive and Aerospace Industries: The rapid expansion of the automotive industry, including the surge in electric vehicle production, is a significant growth driver. The aerospace sector also demands highly precise and reliable machining tools, contributing to the increased demand for advanced lathe chucks (DataIntelo).

Customization and Innovation: There is a growing emphasis on innovation and customization in lathe chucks to meet specific customer requirements. This trend is creating opportunities for manufacturers to differentiate their products and capture new market segments (Source Products).

Segment Analysis

2-Jaw Chucks

2-jaw chucks are primarily used for clamping irregularly shaped workpieces. They are essential in applications where rapid fixturing and faster work cycles are required. These chucks are particularly popular in industries that require quick setup times and efficient operations (FindThisBest).

3-Jaw Chucks

3-jaw chucks are the most common type of lathe chuck, known for their ability to hold workpieces with concentricity. They are ideal for rapid fixturing and are widely used in applications where speed and efficiency are critical. The demand for 3-jaw chucks is expected to remain strong due to their versatility and ease of use (Hobby-Machinist).

4-Jaw Chucks

4-jaw chucks offer the advantage of independent jaw movement, allowing for the clamping of non-axisymmetric workpieces. This feature makes them suitable for precision machining applications where higher accuracy is required. The market for 4-jaw chucks is projected to grow at a CAGR of 5.5% from 2023 to 2032, driven by the increasing demand for precision machining in the automotive and aerospace industries (Verified Market Reports).

Regional Insights

North America

The North American market for lathe chucks is expected to experience steady growth, driven by the expansion of the manufacturing sector and the adoption of advanced machining technologies. The United States, in particular, is a significant contributor to this growth, with a strong presence of key market players (Market Report Analytics).

Europe

Europe is witnessing substantial growth in the lathe chuck market, supported by the increasing demand for precision machining in the automotive and aerospace sectors. Countries such as Germany, the United Kingdom, and France are leading the market, with a focus on innovation and technological advancements (GlobalInfoResearch).

Asia Pacific

The Asia Pacific region is expected to be a major growth driver for the lathe chuck market, with countries like China, India, and Japan leading the way. The expansion of manufacturing capabilities and the adoption of automation technologies are key factors contributing to this growth. The region’s strong industrial base and increasing demand for precision machining solutions make it a lucrative market for lathe chuck manufacturers (Market Report Analytics).

Competitive Landscape

Key market players are focusing on strategic initiatives to strengthen their market position and capitalize on emerging trends. These initiatives include expanding product portfolios, forming strategic partnerships, and enhancing operational efficiencies. Companies are also investing in research and development to introduce innovative and customized solutions that meet evolving customer demands (Source Products).

Conclusion

The lathe chuck market, particularly in the segments of 2-jaw, 3-jaw, and 4-jaw chucks, is poised for significant growth and transformation from 2025 to 2030. The market is driven by technological advancements, automation, and the increasing demand for precision machining solutions. With the growing emphasis on innovation and customization, the lathe chuck market presents numerous opportunities for growth and differentiation in the coming years.

Recommendation

Whether you’re handling round, square, or irregular-shaped workpieces, selecting the right lathe chuck, 2-jaw, 3-jaw, or 4-jaw is key to achieving stability, precision, and efficiency in your machining process.

AUTOGRIP MACHINERY CO., LTD., a leading lathe chuck manufacturer in Taiwan, offers high-performance chucking solutions designed for modern CNC machining needs. Here are three of their flagship products that correspond to the chuck types discussed in this article:

👉 2M Series Wedge Hook Type Long Stroke 2-Jaw Lathe Chuck: Ideal for clamping irregular-shaped workpieces with a longer stroke requirement and strong gripping force.

👉 3L / 3L-A Series Crank Type Extra Long Stroke Thru-Hole 3-Jaw Power Chuck: Perfect for heavy-duty machining with high rigidity and longer stroke for mass production.

👉 4H / 4H-A Series Thru-Hole 4-Jaw Lathe Chuck: Features independently adjustable jaws for precise clamping of square, irregular, or off-center workpieces.