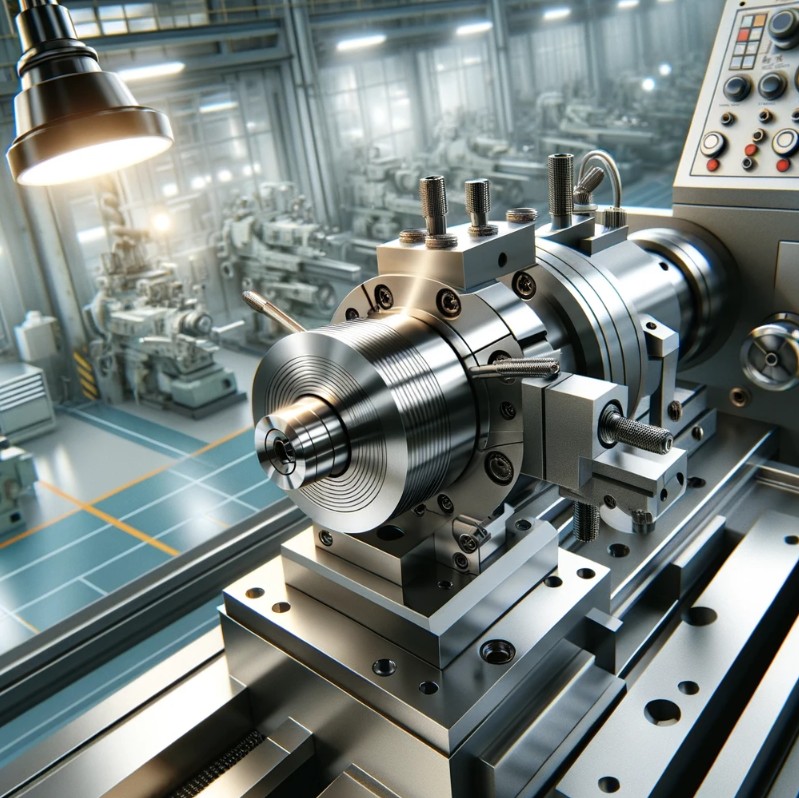

The selection of lathe chucks is a critical decision in machining operations, particularly when precision work is involved. A lathe chuck is a device used to hold the workpiece securely in place while it is being rotated on a lathe machine. The right choice of chuck can significantly impact the quality, accuracy, and efficiency of machining operations. This report provides an in-depth analysis of the factors influencing the selection of lathe chucks for precision work, drawing on various reliable sources.

Key Factors in Selecting Lathe Chucks

- Chuck Type and Application Different types of lathe chucks are designed for specific applications and workpiece shapes. The most common types include three-jaw, four-jaw, and collet chucks. Three-jaw chucks are versatile and self-centering, making them ideal for round workpieces. Four-jaw chucks offer adjustable jaws for irregular shapes, while collet chucks provide high precision and grip for smaller, delicate tasks (Lathe God). Understanding the specific requirements of the machining application is crucial in selecting the appropriate chuck type.

- Precision and Accuracy Precision and accuracy are paramount in precision work. A high-quality chuck with a precise gripping mechanism ensures accurate alignment and consistency during machining operations. Self-centering chucks are recommended for improved accuracy as they automatically align the workpiece (ShunTool). Additionally, the chuck’s clamping force affects the stability and rigidity of the workpiece, with a higher clamping force providing better grip and minimizing vibrations (Lathe God).

- Material and Construction The material and construction of the chuck are critical factors that influence its performance and durability. Chucks are typically made from steel or cast iron. Steel chucks offer higher gripping force and durability, while cast iron chucks provide better vibration damping properties (ShunTool). The choice of material should be based on the specific machining requirements and the expected performance of the chuck.

- Size and Capacity The size and capacity of the chuck must match the size of the lathe machine and the maximum diameter of the workpiece to be machined. It is important to choose a chuck with sufficient capacity to hold workpieces securely. For example, if the workpiece has a diameter of 4 inches, a lathe chuck with a size between 5-6 inches is recommended (ShunTool).

- Mounting Style The mounting style of the chuck should be compatible with the lathe machine. Common mounting styles include threaded mounts, cam-lock mounts, and taper mounts. Ensuring compatibility with the lathe spindle is crucial to avoid any problems during machining (Galeria Aberta).

- Ease of Use and Quick Changeover Ease of use and quick changeover are important considerations, especially in production settings. Chucks that are easy to install and remove can save valuable setup time. Some chucks feature quick-change mechanisms that allow for rapid changeover between different workpieces or machining operations, enhancing productivity and efficiency (Lathe God).

- Maintenance and Durability Regular maintenance of the chuck is essential to ensure its longevity and performance. This includes cleaning, inspecting for wear and tear, lubricating moving parts, and checking for alignment (Lathe God). Choosing a chuck made from durable materials can also contribute to its longevity and reliability (Galeria Aberta).

Conclusion

Selecting the right lathe chuck for precision work involves careful consideration of various factors, including the chuck type, precision and accuracy, material and construction, size and capacity, mounting style, ease of use, and maintenance. By taking these factors into account, machinists can choose a chuck that ensures optimal performance, accuracy, and efficiency during machining operations. Investing in high-quality lathe chucks is essential for achieving excellent results in precision work.

When it comes to unmatched precision and durability, AUTOGRIP MACHINERY CO., LTD. stands out as a leader in CNC chuck manufacturing. Their 2 Jaw Chucks are specifically engineered for applications requiring exceptional grip and flexibility, ideal for irregular or asymmetric workpieces. The 3 Jaw Chucks, known for their self-centering capabilities, provide outstanding performance for round or symmetrical components, ensuring precise alignment and stability. For larger or more complex machining tasks, AUTOGRIP’s 4 Jaw Chucks offer superior adjustability and a high clamping force, making them perfect for heavy-duty operations or non-cylindrical parts. Each of these products is meticulously designed with robust materials and advanced engineering to meet the diverse needs of machinists worldwide. Explore the full range of AUTOGRIP products to elevate your machining precision and efficiency: 2 Jaw Chucks, 3 Jaw Chucks, and 4 Jaw Chucks. Welcome to choose Autogrip Chuck today!